Relevance and Accuracy in Custom Metal Stamping Dies

In the field of metal fabrication, custom metal stamping dies are key instruments. They enable precision and accuracy during the creation of metal components. By employing custom dies, each stamped part is produced under strict quality control, ensuring that each component is crafted to the specifications of its purpose. Accuracy is critical during metal working of complex parts like the custom aluminum parts and high-tolerance stainless steel die cast transmission gears.

Affordable Mass Production

One of the major benefits of using custom metal stamping dies is the profitability achieved by mass production. Die production is expensive, but once it is created, it can be used over and over to produce thousands or even millions of identical components. It is easy to see how this system saves on capital cost as well as labor. Furthermore, rapid cycle times for stamping die operation help to accommodate tight deadlines on production.

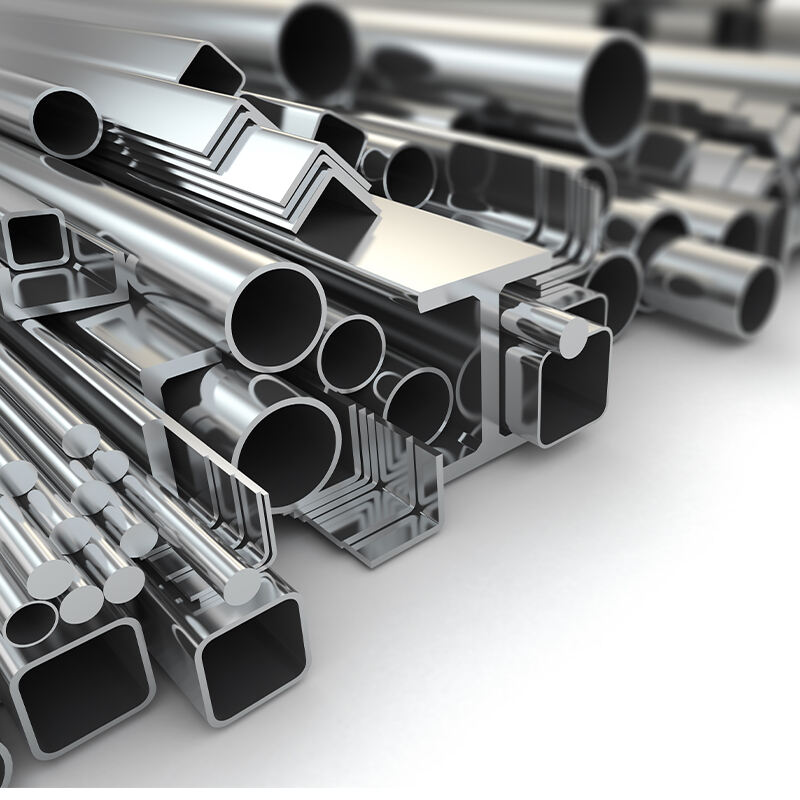

Flexibility In Use Of Different Materials

The custom metal stamping dies we create are flexible in the material use aspect. We can work with different types of metals which include, stainless steel, aluminum, and zinc among others to design parts that meet specific performance goals. Our custom dies can accommodate the strength and durability needed in industrial equipment as well as the aesthetics in decorative hooks.

TCJH Innovation and Quality Focus

At TCJH, we strive to offer the best custom metal stamping dies, and with that comes strict standards. Our delineated product series does not miss out on a key precision factor which lowers the standard, and hence we offer an array of custom designed dies to cater to varying thresholds in the industry. From precision stamped shelf brackets to high precision anodized aluminum L shape brackets, we aim to set the benchmark in metal fabrication that delivers positive outcomes.

Copyright © 2024 by Xiamen Tongchengjianhui Industry & Trade Co., Ltd. - Privacy policy